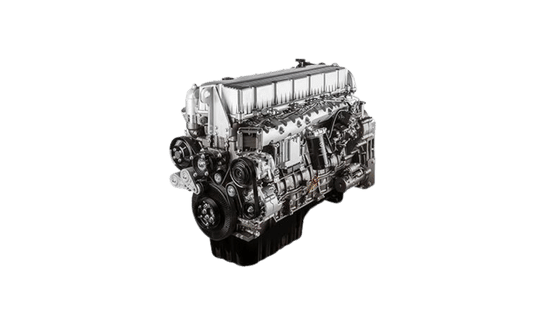

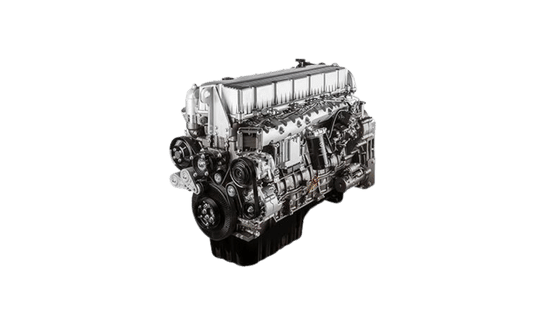

Description

The SE series industrial Diesel engine for commercial generators was designed through a collaboration with SMAN and Austria AVL. Together we applied internationally advanced engine technology to create first-class equipment. This series represents a brand new engine platform created by following SAIC Motor manufacturing standards and installing an optional electronically controlled high pressure common rail and electronic governing mechanical pump fuel system. This engine series is noted for its safe, reliable, and high powered performance capabilities. Compared to similarly powered engines, it offers significant efficiency advantages and it is applicable for high and medium end common generator sets of 250-300 kW.

Outline dimensional drawing

Technical parameters

Engine model |

| 12SE460D | 12SE500D |

Engine Type |

| In-Lineh, Water-Cooled, Four-Stroke, Direct Injection, Four-Valve | |

Aspiration Type |

| Air-Air Intercooler | |

Number of Cylinders×Bore×Stroke | mm | 6×128×153 | |

Cylinder Liner Type |

| Wet Liner | |

Total Displacement | L | 11.8 | |

Speed Governing Rate | % | 0 ~ 5 | ≤1 |

Speed | r/min | 1500 | |

Max. Power (Standby) | kW | 338 | 370 |

Min. BSFC | g/kW.h | 192 | |

Exhaust Smoke | FSN | ≤1.5 | |

Coolant Capacity | L | 23.2 | |

Oil Capacity | L | 37 | |

Oil Consumption | g/kW.h | ≤0.3 | |

Firing Order (From Free End) |

| 1-5-3-6-2-4 | |

Crankshaft Rotation |

| Anticlockwise (Viewed from Flywheel End) | |

Emissions Level |

| TIER Ⅱ | TIER Ⅲ |

Noise | dB (A) | 105 | |

Net Weight | kg | 1165 | |

Flywheel and Flywheel House |

| SAE14# & SAE1# | |

Features

- Featuring advanced technology, the engine adopts four valves per cylinder, an overhead camshaft, bedplate high strength cylinder block and rear gear chamber. The maximum allowable peak pressure is 190 bar. We utilize automatic production lines of MAG and other international first-class brands, an MES control system and engine manufacturing quality control system of German Volkswagen, the engine is high quality and delivers excellent consistency.

- The cylinder block has a B10 service life of over 15000 working hours.

- The single overhead camshaft interacts with the roller rock arm. The valve clearance regulating interval is doubled. With a closed valve clearance design, cracking connecting rod and multiple oil filtering, the maintenance is simple.

- Convenient maintenance

- The whole machine can work normally at ambient temperatures of up to 40℃. Without intake air heating auxiliary device, the cold starting temperature limit is -15℃, delivering strong environmental adaptability.

- This series engine meets the Off-Road Euro Ⅱ Emissions Standard.